industrial materials

HIMELON® Non-Woven Fabric

HIMELON is a trusted and long-selling non-woven fabric brand in prevents NVH/BSR (irregular) noise. Customers in Japan love and use HIMELON for over 50 years.

HIMELON is widely used in lots of industries such as automobiles and electrical appliances and boasts NO.1 share in Japan.

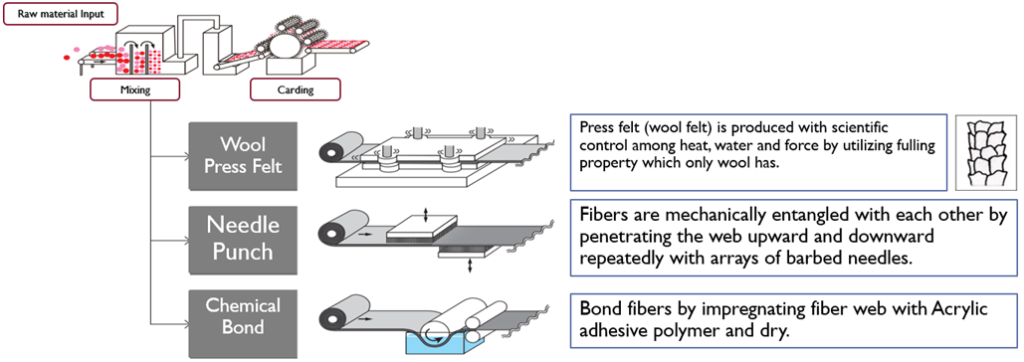

*3 types of manufacturing methods, HIMELON is produced with 3 types of manufacturing methods.

HIMELON has moderate voids between the fiber, with a soft texture and cushioning.

Chemical bond type glues fibers with resin, so fluff issues can be reduced with excellent fabrication workability.

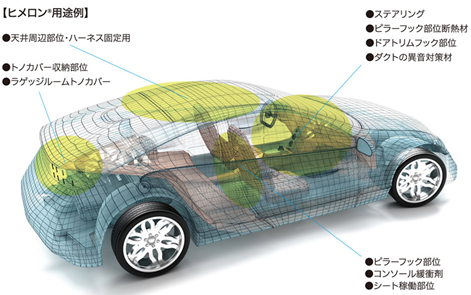

Application examples: cushioning, dust protection, blinding and etc.

HIMELON is widely used for automotive, audio, home appliance, and OA equipment.

【Features of Himelon】

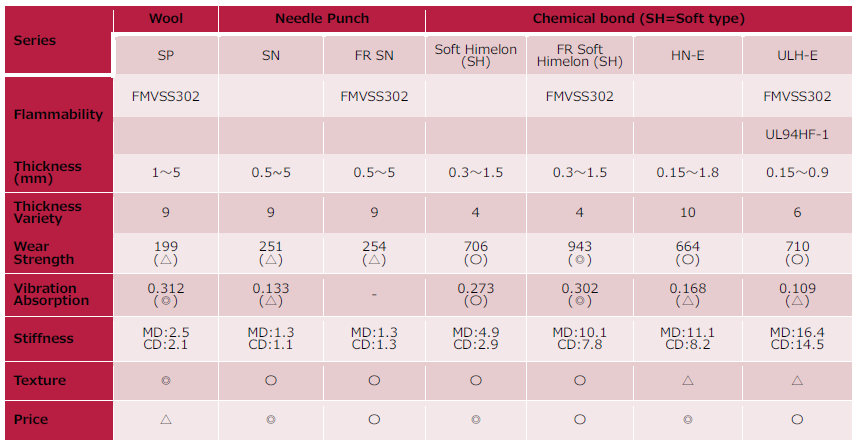

- FMVSS302、UL94HF-1 flame-retardant (Non-flame retardant type as well)

- Free for halogen, formaldehyde, nonylphenol

- High cushioning property (Wool, Needle-punch, soft chemical)

- Excellent stick-slip characteristic

- Excellent fabrication workability (Chemical bond)

【Benefits of Using Himelon】

- You can be completed with only Himelon for NVH countermeasures due to advanced vibration absorbent, strength and durability.

- High quality and low defects ratio. Can reduction of costs for defective products.

- 3 types 59 items: Easy to handle wide and various uses, and save design time and cost.

- There are many experiences of adoption for automobiles and home appliances. Various data are available.

You can save investigation time and cost. - Weatherability is better than foam materials. Lightweight compared with rubber materials.

【Line-up for Himelon】

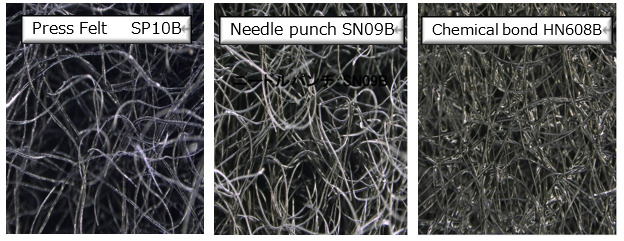

1. SP series Wool Press Felt

Press felt mainly is made with natural materials like wool and rayon.

It is effective against hitting and rubbing noise with a soft texture.

The vibration absorption value is the highest among the Himelon series.

SP series has Self-extinguishing properties which are characteristic of wool,

and conform to FMVSS302 Flame retardant.

Appearance is good and has the experience to use for a visible part like column cover.

| SP series | Weight (g/㎡) | Thickness (mm) | Widths&Lengths (m x m |

| SP10B | 230 | 1.0 | 0.9 x about 45 |

| SP12B | 285 | 1.2 | 0.9 x about 40 |

| SP15B | 370 | 1.5 | 0.9 x about 40 |

| SP18B | 425 | 1.8 | 0.9 x about 38 |

| SP23B | 510 | 2.3 | 0.9 x about 20 |

| SP30B | 720 | 3.0 | 0.9 x about 20 |

| SP40B | 960 | 4.0 | 0.9 x about 20 |

| SP50B | 1200 | 5.0 | 0.9 x about 20 |

2. Soft Himelon SH series Chemical Bond Felt

Newly developed material for Automotive interior NVH/BSR purpose.

Improve chemical bond type hardness softer in order to follow the curve parts.

Excellent in vibration absorption, wear resistance, weatherability, less fluff, and well fabrication workability.

Flame retardant type Conform to FMVSS302.

| Type: General | Weight (g/㎡) | Thickness (mm) | Widths&Lengths (m x m) |

| SH606B | 55 | 0.30 | 1.0 x 50 |

| SH608B | 85 | 0.50 | 1.0 x 50 |

| SH620B | 180 | 1.00 | 1.0 x 50 |

| SH630B | 260 | 1.50 | 1.0 x 1.0 |

| Type: Flame Retardant | Weight (g/㎡) | Thickness (mm) | Widths&Lengths (m x m) |

| SH606BN | 60 | 0.30 | 1.0 x 50 |

| SH608BN | 90 | 0.50 | 1.0 x 50 |

| SH620BN | 200 | 1.00 | 1.0 x 50 |

| SH630BN | 280 | 1.50 | 1.0 x 1.0 |

・Comparison with conventional products

| General Soft HIMELON SH620B (t1.0) | General HIMELON HN620B (t0.9) | Fire Retardant Soft HIMELON SH620BN (t.1.0) | Fire Retardant HIMELON N9795B (t.0.9) | |

| UL Standard | – | – | – | UL94HF-1 |

| FMVSS Standard | – | – | FMVSS 302 | FMVSS 302 |

| Abrasion Test (JISL1096 A-1) | 706times (1.0mmt) | 664times (0.9mmt) | 943times (1.0mmt) | 710times (0.9mmt) |

| Bending Rigidity(mN) (JIS L1096 99 8.22 1 A) | Warp: 4.9 Weft: 2.9 | Warp:11.1 Weft: 8.2 | Warp: 10.1 Weft: 7.8 | Warp: 16.4 Weft: 14.5 |

| Lighting Resistance | Minimal discoloration | Minimal discoloration | Minimal discoloration | Minimal discoloration |

| Vibration Absorption | 0.2730 (1.0mmt) | 0.1684 (0.9mmt) | 0.3016 (1.0mmt) | 0.1092 (0.9mmt) |

3. SN series Needle Punch Felt

This is made of polyester Needle punch Non-woven fabrics.

Excellent candidacy, soft texture, and followability of bent parts.

Higher tensile strength than other needle punch products due to reinforcing included.

Conform to FMVSS302 for flame resisting type.

Line-up is 9 types general and flame resisting each.

| SN series | Weight (g/㎡) | Thickness (mm) | Widths&Lengths (m x m) |

| SN05B(N) | 120 | 0.5 | 1.0 x about 50 |

| SN07B(N) | 140 | 0.7 | 1.0 x about 50 |

| SN09B(N) | 150 | 0.9 | 1.0 x about 50 |

| SN15B(N) | 225 | 1.5 | 1.0 x about 50 |

| SN20B(N) | 300 | 2.0 | 1.0 x about 50 |

| SN25B(N) | 400 | 2.5 | 1.0 x about 25 |

| SN30B(N) | 500 | 3.0 | 1.0 x about 25 |

| SN40B(N) | 670 | 4.0 | 1.0 x about 20 |

| SN50B(N) | 830 | 5.0 | 1.0 x about 20 |

4. HN-E series -Chemical Bond Felt

This is the longest history in the Himelon series.

Chemical bond non-woven fabrics in which short fibers are bonded in sheets shape with resigning.

Excellent wear proof, less fluff, and great processability.

The thinnest is 0.15mmt(Reference value) and you can use narrow gap parts.

Total 10 type line-ups.

| HN-E series | Weight (g/㎡) | Thickness (mm) | Widths&Lengths (m x m) |

| HN603B | 30 | 0.15 | 1.0 x 50 |

| HN604B | 45 | 0.25 | 1.0 x 50 |

| HN606B | 60 | 0.35 | 1.0 x 50 |

| HN608B | 75 | 0.45 | 1.0 x 50 |

| HN611B | 100 | 0.55 | 1.0 x 50 |

| HN616B | 130 | 0.70 | 1.0 x 50 |

| HN620B | 180 | 0.90 | 1.0 x 50 |

| HN625B | 225 | 1.20 | 1.0 x 50 |

| HN630B | 280 | 1.50 | 1.0 x 1.0 |

| HN640B | 335 | 1.80 | 1.0 x 1.0 |

5. ULH-E series Chemical Bond Felt

The type of flame resisting for HN-E conforms to FMVSS302, UL94HF-1.

Chemical bond non-woven fabrics in which short fibers are bonded in sheets shape with resigning.

Excellent wear proof, less fluff, and great processability.

The thinnest is 0.15mmt(Reference value) and you can use narrow gap parts.

| ULH-E series | Weight (g/㎡) | Thickness (mm) | Widths&Lengths (m x m) |

| N9095B | 35 | 0.15 | 1.0 x 50 |

| N9195B | 50 | 0.25 | 1.0 x 50 |

| N9295B | 65 | 0.35 | 1.0 x 50 |

| N9495B | 90 | 0.50 | 1.0 x 50 |

| N9595B | 130 | 0.70 | 1.0 x 50 |

| N9795B | 200 | 0.90 | 1.0 x 50 |